Metal stamping remains one of the most reliable and cost-effective manufacturing methods for producing high-precision components in the automotive industry. As vehicle platforms evolve toward higher performance, tight tolerances, and lightweight materials, the demand for stable and scalable stamping capabilities continues to grow.

This guide provides an easy-to-understand overview of metal stamping processes, design considerations, and quality-control practices—ideal for buyers, engineers, and procurement teams looking to understand how a modern stamping facility supports mass production.

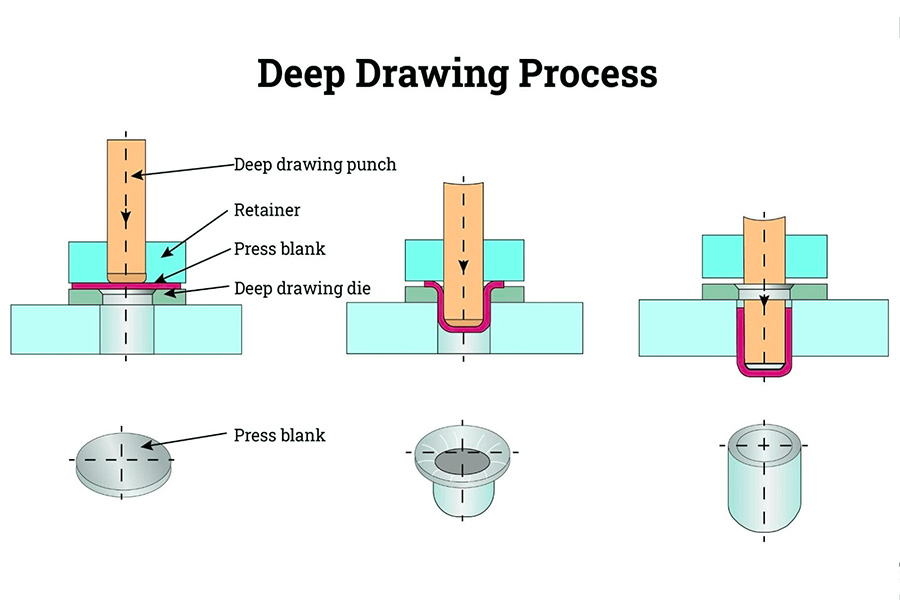

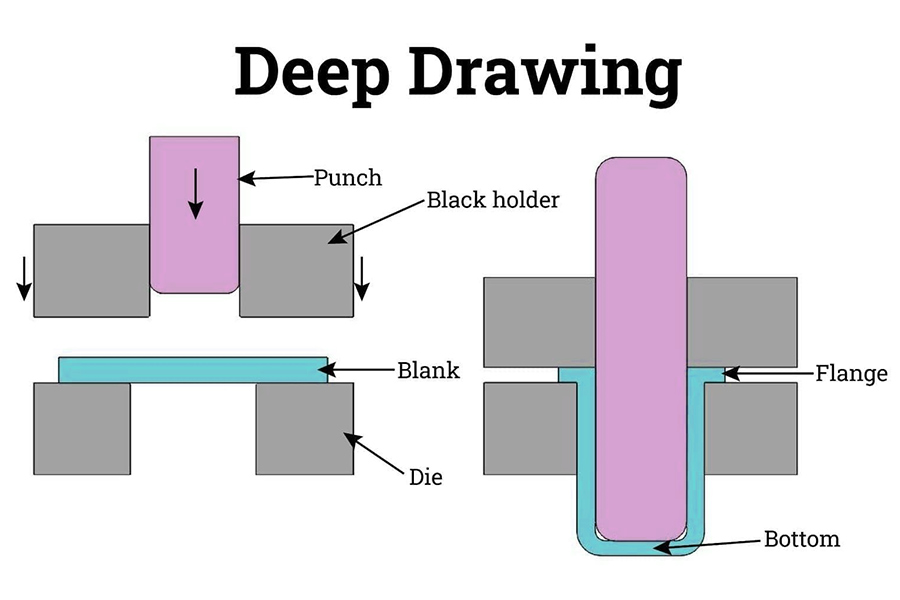

Metal stamping uses dies and stamping presses to transform flat metal sheets into desired shapes through cutting, bending, forming, and drawing.

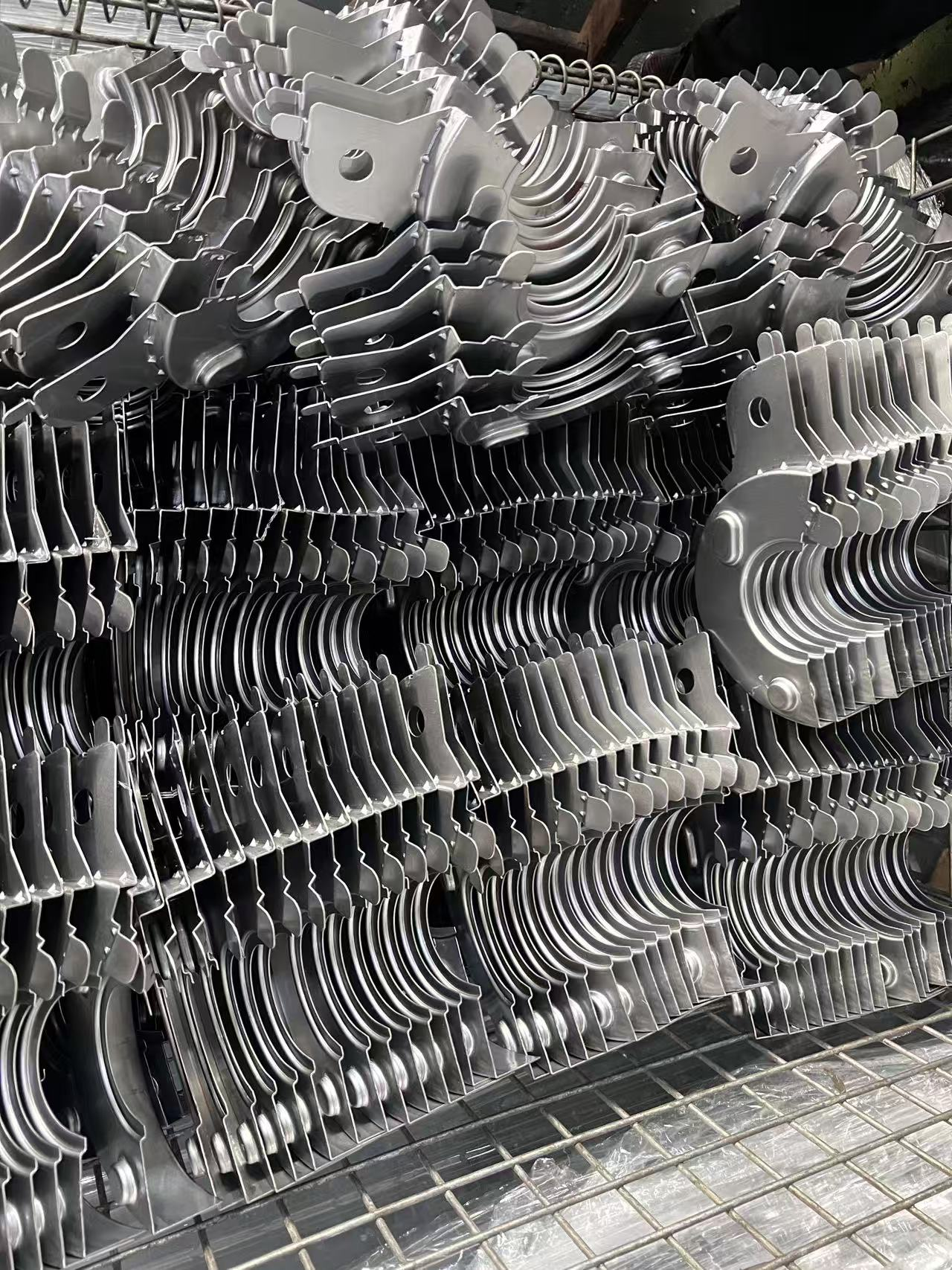

It is widely used for automotive structural components, transmission housings, engine-related parts, brackets, and precision functional pieces.

Key advantages include:

High repeatability

Excellent dimensional consistency

Low cost per unit in mass production

Ability to process steel, stainless steel, aluminum, and coated materials

A continuous strip moves through multiple stations in one tool, completing several forming operations in a single stroke.

Ideal for medium and high-volume production requiring precision and efficiency.

Used for producing deeper, hollow components without welding.

Suitable for applications requiring strength, leak-proof structures, or complex geometry.

For parts requiring micron-level dimensional control, surface uniformity, and tight tolerance management.

Modern metal stamping supports a wide range of automotive systems, including:

Powertrain & transmission structures

Engine-related components

Chassis brackets and mounting plates

Functional housings and covers

Lightweight aluminum components

By integrating advanced tools and quality systems, stamping manufacturers can support both standard and custom designs.

Accurate dies ensure stable dimensional consistency throughout large production batches.

Strict inspection of coils and sheets minimizes variations from suppliers.

Sensors, press tonnage monitoring, and visual systems help detect abnormalities early.

CMMs, profile projectors, and surface testers verify every critical dimension and finish level.

Well-maintained tools and documented process parameters are essential for OEM-grade mass production.

A reliable partner brings:

Strong engineering support

Stable production capacity

Cost-effective manufacturing

Consistent quality control

Flexible customization options

Whether you need small precision components or large structural stampings, choosing a capable stamping manufacturer ensures safer and more efficient automotive production.

Metal stamping is a key foundation of modern automotive manufacturing, balancing speed, accuracy, and cost. With the right processes, tooling, and quality systems, a stamping factory can deliver consistent performance across thousands or millions of parts.