OEM Automotive & Precision Machined Parts Supplier Since 1998

”

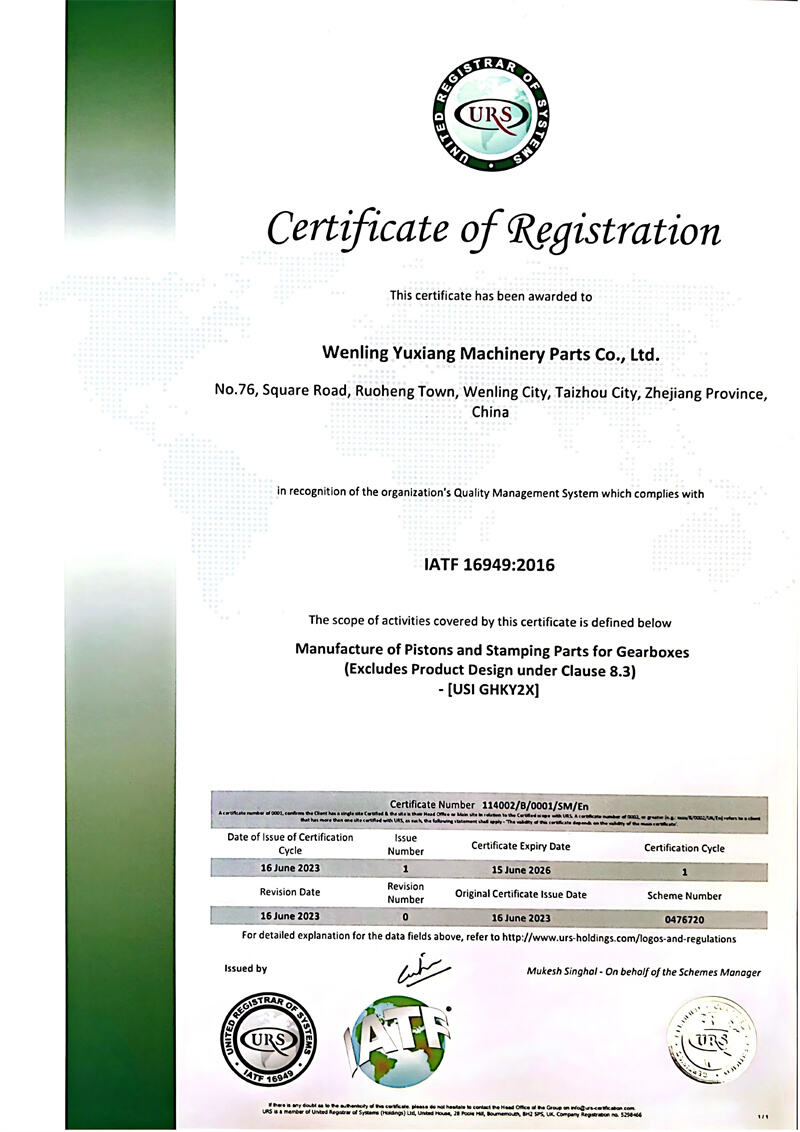

IATF16949 Certified | 1.5M Units Annual Output | Stamping, Machining & Transmission Components”

High-quality stamped bearing baffle, 1.2mm thick, designed for automotive applications. After precision stamping, internal threads are tapped for secure assembly, ensuring reliable performance and dimensional accuracy in critical bearing assemblies.

|

Parameter |

Details |

|

Manufacturing Process |

Stamp |

|

Cleanliness Standards |

EU/US |

|

Maximum Dimensional Tolerance |

+0.01mm |

·Material selection – high-strength steel.

·Precision stamping using CNC punch press.

·Tapping internal threads with CNC or manual taps.

·Deburring and cleaning to meet cleanliness standards.

·Final inspection using 3D coordinate measuring machine to ensure dimensional accuracy (±0.01mm).

Used in automotive bearing assemblies to secure components, prevent misalignment, and maintain reliable rotational performance.

·Precision stamping and tapped threads ensure secure fit and high reliability (±0.01mm).

·1.2mm thick steel provides strength and durability.

·Optional corrosion-resistant surface treatments for long-term performance.

·Cleanliness and precision meet strict automotive standards.

·Supports OEM and aftermarket automotive applications.

Each unit is individually placed in an anti-static bag, then packed into cartons, and finally secured on wooden pallets for bulk shipments.

Shipping:

Domestic: Delivered via SF Express within 2–3 days, with tracking available.

Export: FOB Ningbo/Shanghai; delivery time 15–20 days by sea, or 3–5 days by air via DHL/FedEx

24-hour technical support via phone (+86-17681682039) or email ([email protected]). Free replacement for non-conforming products within 30 days of receipt.

· Do you supply components to major OEMs and Tier 1 companies?

Yes, we supply components to OEMs such as Chery and Wanliyang.”

·What materials are used in your products?

We use high-quality steel or alloy materials suitable for the specific application.

·Can you customize the products?

Yes, we offer OEM and contract manufacturing to meet your requirements.

·What is the standard delivery time?

Domestic: 2–3 days with tracking.

Export: 15–20 days by sea, 3–5 days by air.

·How are the products packaged?

Each unit is carefully packed, usually with protective bags, cartons, and pallets for bulk orders

·Are your products tested for quality?

Yes, all products undergo strict quality inspection, including dimensional checks and surface treatment verification.

·Do you provide technical support?

Yes, our team can assist with installation guidance, compatibility questions, and process recommendations.

·What is the warranty or service policy?

Standard warranty and after-sales support are provided; details depend on the product type.